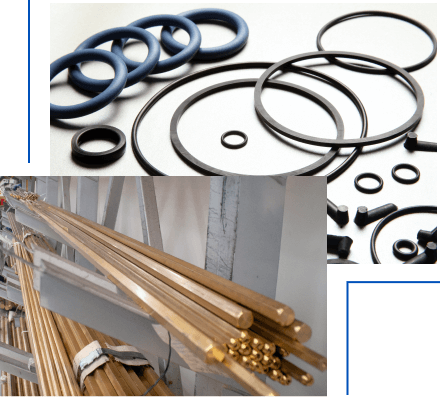

HOW WE DO IT

At IMOPAC, our entire production process takes place in-house, giving us full control over every stage and ensuring a high-quality final product.

From design and manufacturing to assembly, storage, and management, every phase is optimized for efficiency and precision. We don’t just produce—we ensure that every piece meets the highest standards before reaching our clients.

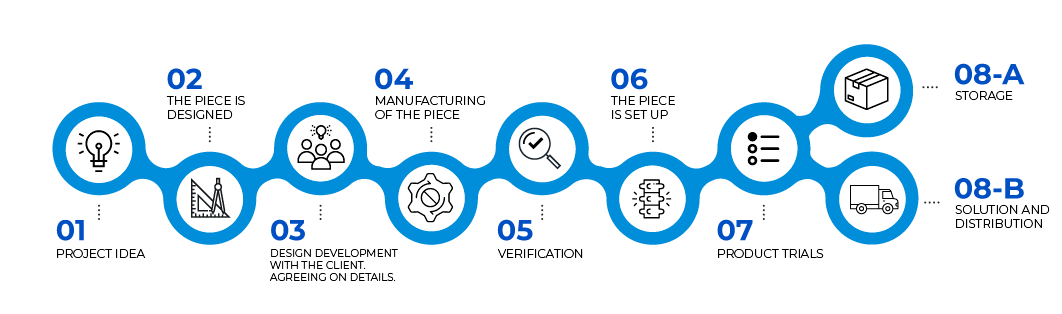

MANUFACTURING & ASSEMBLY

The heart of IMOPAC. Above all, we are manufacturers. And we manufacture exclusively with high-precision CNC lathes.

For us, manufacturing is the perfect balance between technology and craftsmanship. That’s why each part goes through manual finishing processes, where human expertise makes the difference. This allows us to achieve a level of detail that no machine can replicate.

Our assembly process reflects IMOPAC’s philosophy: to deliver a product tailored to each client’s needs.

We are not a standard assembly line. Each piece is carefully assembled by hand, ensuring it meets the specific requirements of every project. Additionally, every product undergoes rigorous quality and safety testing, guaranteeing its reliability in any application.

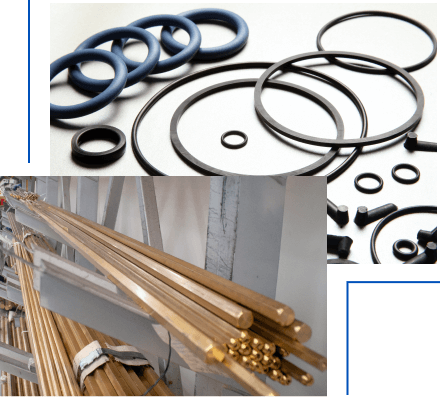

WAREHOUSE AND DISTRIBUTION

At IMOPAC, we maintain a high inventory level, allowing us to provide shorter lead times and greater flexibility for our customers.

We ensure fast delivery times not only in Spain but also on an international scale. We are part of large-scale global projects, with a strong presence in Portugal, Italy, and France, working alongside strategic distributors to deliver localized service with global standards.

IMOPAC stands for Spanish industrial quality with international reach.

VERSATILITY IN ASSEMBLY

High stock capacity and fast service

Speed is one of IMOPAC’s defining values. Today’s industry demands immediacy, but ensuring it is becoming increasingly difficult. That’s why we have developed a flexible assembly model, allowing us to adapt materials and components in record time to meet any requirement.

Our large storage capacity and process optimization enable us to maintain immediate availability and provide a service aligned with the quality of our products.