Threads are the most common mechanical joining system in pipes, fittings, and couplings. At first glance they may look the same, but choosing the correct thread type is essential to ensure compatibility, tightness, and safety of the installation.

An error in selection can cause leaks, breakages, and unplanned maintenance downtime. That’s why in this article we review the most widely used thread types in industry, their differences, and how to identify which one is right for each application.

Before looking at each standard in detail, it is worth understanding why so many thread variants exist. Their evolution responds to different industrial traditions, regional standards, and technical requirements. In Europe, metric and BSP threads became consolidated, while in the United States NPT and UN/UNF threads were adopted. In addition, the shape of the thread (parallel or tapered), the flank angle, and the measuring system (millimeters or inches) directly affect compatibility. Identifying these factors from the outset is key to avoiding assembly problems and ensuring reliable sealing.

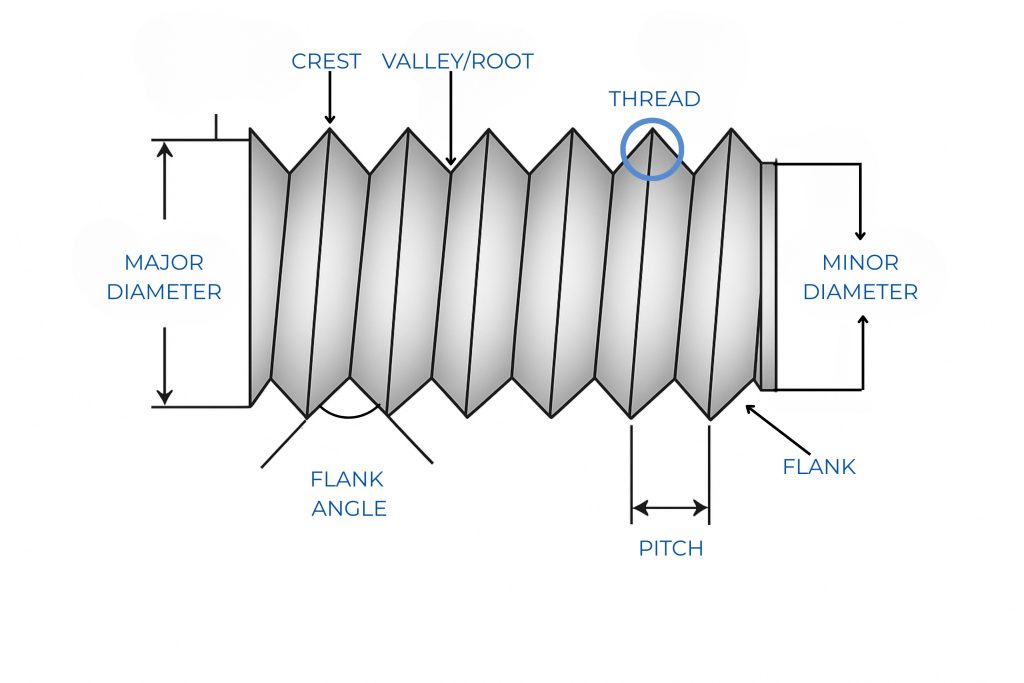

Parts of a Thread

All threads share a series of common elements

- Crest: the top of the thread, the peak of each turn.

- Root (Valley): the lowest point between two consecutive crests.

- Thread: each helical ridge forming the screw.

- Flank: the lateral surface of the thread, which can form different angles depending on the standard.

- Flank angle: the angle formed by both flanks of a thread, key to distinguishing thread types.

- Pitch: the distance between two consecutive crests, measured parallel to the axis.

- Major diameter: maximum distance between opposite crests.

- Minor diameter: minimum distance between opposite roots.

How a Thread Works

A thread functions as a helical inclined plane wrapped around a cylinder. This geometry transforms a rotational movement into linear motion or clamping force.

Key principles:

- Force transmission: when turning a screw or nut, the thread slides over the opposite flank. The flank angle and pitch determine how the load is distributed, allowing force multiplication.

- Locking and holding: friction between flanks prevents loosening. Fine threads (UNF) provide more contact in less travel, increasing resistance to loosening.

- Sealing (for fluid threads): parallel threads (BSPP, UN/UNF, Metric) require an additional gasket; tapered threads (NPT, BSPT) achieve sealing by deformation during tightening.

- Reversibility: threads can be assembled and disassembled without damage, provided torque limits are respected and no excessive wear occurs.

Main Thread Standards in Industry

Although dozens of variants exist, in practice engineers and technicians usually work with five main standards:

Metric ISO (M)

- Origin: Europe.

- Characteristics: 60° flank angle, dimensions in millimeters (e.g., M10x1).

- Applications: general mechanical connections, fittings in European industrial equipment.

- Sealing: requires gasket or washer.

BSP (British Standard Pipe)

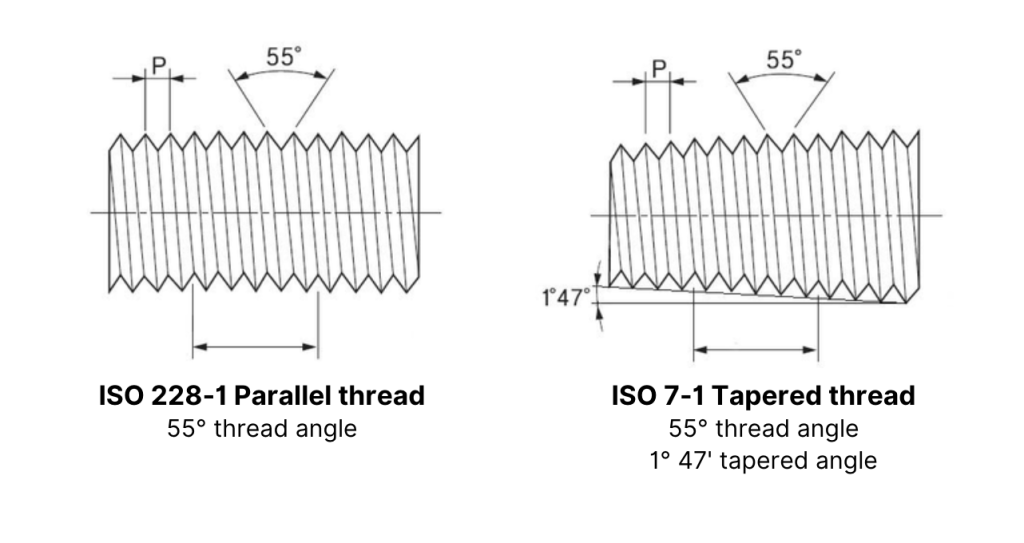

- Versions: BSPP (parallel), BSPT (tapered).

- Angle: 55°.

- Applications: widely used in hydraulics and pneumatics in Europe.

- Sealing:

- BSPP → parallel sealing with gasket or O-ring.

- BSPT → sealing by interference when tightening (tapered).

NPT (National Pipe Tapered)

- Origin: United States.

- Angle: 60°.

- Applications: high-pressure environments, oil & gas, heavy machinery.

- Sealing: tapered, sealing achieved by tightening; usually reinforced with PTFE tape or sealant.

UN / UNF (Unified National / Unified Fine)

- Origin: American standard.

- Characteristics: 60° flank angle, coarse pitch (UN) or fine pitch (UNF).

- Applications: machinery, hydraulics, automotive, requiring strong mechanical fastening.

- Sealing: parallel, typically with gasket or washer.

Other special threads

- PG: common in electrical conduit fittings.

- RC/Rp: DIN/ISO standardized pipe thread variants.

- Custom threads: some manufacturers design proprietary thread profiles.

Key Differences Between Thread Types

When selecting a thread, four factors are essential:

- Flank angle → BSP (55°) vs NPT/UN/Metric (60°).

- Parallel vs tapered → tapered (NPT, BSPT) seal by interference; parallel (BSPP, Metric) require gaskets.

- Measurement system → Metric (mm) vs Imperial (inches).

- Compatibility → standards are not interchangeable (e.g., NPT and BSP are similar in appearance but not compatible).

Comparative Table of Thread Types

| Thread type | Flank angle | Form | Units | Sealing | Typical applications |

|---|---|---|---|---|---|

| Metric ISO | 60° | Parallel | Millimeters | Washer or gasket | European machinery |

| BSPP | 55° | Parallel | Inches | Gasket or O-ring | Pneumatics, hydraulics |

| BSPT | 55° | Tapered | Inches | Interference fit | Medium-pressure hydraulics |

| NPT | 60° | Tapered | Inches | Interference + sealant | Oil, gas, high pressure |

| UN / UNF | 60° | Parallel | Inches | Washer or gasket | Automotive, hydraulics |

Risks and Failures in Thread Use

Despite being a reliable and standardized joining system, improper use or design can cause serious issues:

- Over-torque damage: excessive tightening deforms or breaks threads, increasing risk of galling in stainless steel.

- Leaks from mismatched standards: BSP and NPT may look similar, but their angles differ, leading to leaks or deformation.

- Wear from repeated assembly: especially in softer materials like brass or aluminum, reducing sealing capacity.

- Corrosion and seizure: moisture or chemicals can corrode or lock threads. Stainless steel is prone to galling.

- Vibration loosening: continuous vibration causes gradual loosening, micro-leaks, or disconnections.

- Damaged or dirty threads: contamination or mechanical damage reduces sealing and makes assembly difficult.

Conclusions

There is no universally “better” thread: the right one depends on application, working pressure, fluid, and applicable standards.

At IMOPAC, due to the characteristics of our sector, we mainly work with BSP threads and to a lesser extent with NPT threads. However, as manufacturers, we are capable of producing any type of thread.

It is essential that threads are compatible to ensure system tightness and efficiency. Our Technical Department can advise you in selecting the right connection for your installation.

Do you have doubts about which thread you need? Contact us and we will help you choose wisely.

Also, follow us on our LinkedIn page to stay up to date with news, updates, and practical guid